What scientists from the University of Pennsylvania, the University of Illinois and the University of Cambridge managed to do stands out from the general row in that the process of creating a structured material was controlled at the level of individual atoms. And as a result, a new material was obtained, called "metal wood", which is stronger than titanium, but five times lighter than nickel, from which it is actually made.

The phrase "stronger than titanium" is certainly a cliché, but in this case it is the purest truth.

Although titanium itself could be 10 times stronger, if its structure was ideal. The secret of the strength of the new material can be seen in ordinary woods. Pure cellulose, which itself is a soft material, acquires a fairly high strength when formed into a wood structure. And some of the types of artificial cellulosic materials are comparable in strength to not the worst steel.

By the way, the scientists who created the "metal tree" did not pursue the goal of creating this particular material; during their research, they were looking for and working out new methods of creating a metal porous structure resembling the structure of wood. In the past, molten metal foaming or 3D printing has been used to achieve this effect, providing an accuracy of several hundred nanometers. However, both methods have their drawbacks, by foaming it is very difficult to achieve a uniform density distribution of the material, and the 3D printing process is extremely slow for use in industrial production.

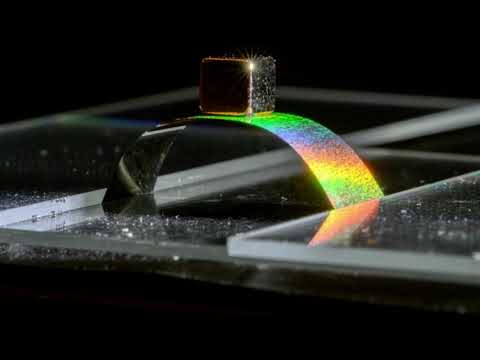

According to previous studies, reducing the size of its structural units plays a key role in increasing the strength of a material. The researchers managed to achieve this by using plastic nanoparticles, several tens of nanometers in size, evenly mixed in water. When water evaporates, these spherical particles are ordered in the form of a geometrically regular structure, after which a layer of nickel is galvanically deposited on their surface, which gradually fills the entire space between the particles. After that, the plastic is removed by dissolving and a mesh of the finest metal bridges remains. The filling factor of the space with metal does not exceed 30 percent, the remaining 70 percent falls on the void, and this is enough for the resulting material to have a density that allows it to float on the surface of the water.

Until recently, scientists managed to create samples of "metal wood" in the form of foil, with an area of about one square centimeter. And the very process of creating such a material is extremely expensive. However, further research is aimed at making the material cheaper by increasing production volumes. In parallel with this, scientists are investigating the properties of "metal wood" and its behavior under the influence of extreme mechanical stress.

Promotional video:

Another interesting potential of this technology is that the empty space in the metal structure can be filled with another material. Naturally, a metal structure filled with a liquid or solid electrolyte can become an element of a very large storage battery that can power the device in which it is built for a very long time.