Everyone has probably seen this kind of structure and you know that this is not a pipe at all and no smoke comes out of it.

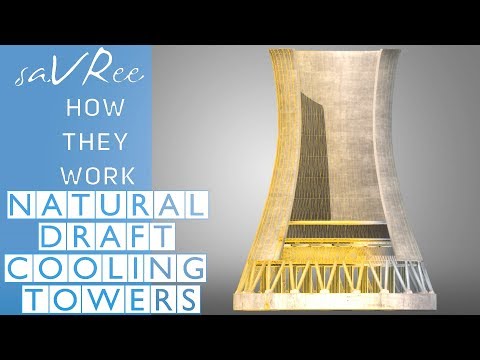

But let's still look at the principle of operation and the internal structure of the cooling tower.

Cooling towers are special devices for cooling large amounts of water through a directed air flow. They are also called cooling towers - this sounds more understandable.

This is one of the most effective devices for cooling water in recycling water supply systems of industrial enterprises. The high tower creates the very draft of air that is necessary to effectively cool the circulating water. Exhaust towers are used to create natural draft due to the difference in specific gravity of the air entering the cooling tower and the heated air leaving the cooling tower. A drainage tank is located under the sprinkler. Water is supplied to the water distribution device through risers located in the center of the cooling tower. Thanks to the high tower, one part of the vapor is recycled, while the other is carried away by the wind. Because of this, dampness, fog and icing does not form in the area in winter, although ice may appear around irrigation devices.

Cooling towers were used to extract salt by evaporation. Currently, these structures are used for minor cooling of warm water. "Minor" means that after the cooling tower the water does not become icy as in the chiller (+7 degrees). The temperature of water entering the cooling tower is about 40-50 degrees, after the cooling tower - 25-30 degrees (at best).

The need to cool warm water arises if it is required by the technological process in production or in the case of cooling water for a chiller with a water condenser.

Promotional video:

There are two types of cooling towers: actual cooling towers and dry cooling towers ("drycooler").

Thermal power plants, nuclear power plants, industrial enterprises consume a huge amount of industrial water, primarily for cooling components and assemblies. Naturally, the water heats up. Since water often moves in a closed loop (that is, it does not drain into the river, but goes back to cool the units), it should be cooled. This is necessary, first of all, to increase the cooling efficiency - the colder the water, the better it will cool the equipment.

For the purpose of partial cooling of water, cooling towers are used.

The principle of the cooling tower is quite simple

The cooling process in cooling towers occurs due to the partial evaporation of water and heat exchange with air. The water in the cooling tower flows down the sprinkler and escapes in drops or a thin film. At this time, air flows along the sprinkler. there is such a pattern: in cooling towers, when 1% of water evaporates, the temperature of the remaining water decreases by 6 C. The loss of liquid is replenished by an external source. Moreover, fresh water, if necessary, is processed (filtered).

The most complex element of a cooling tower is an exhaust tower, the design of which is mainly determined by the material from which it is built.

Hot water enters the cooling tower, where, depending on the type and design of the cooling tower, it is cooled to the required temperature. Cooling of water can be carried out:

- reverse flow of atmospheric air (fan cooling towers);

- due to the spraying of hot water by nozzles onto a special filler with a developed area, over which the water spreads in a thin film and due to its slow flow - it is cooled (tower, atmospheric cooling towers);

- by spraying water in special channels and natural entrainment of atmospheric air (ejection cooling towers).

In any case, water comes into contact with air, to which it gives off part of its heat and thereby, lowering its temperature. Having acquired the required temperature, the water flows back to cool heat exchangers or other devices in which it is necessary to lower the temperature.

Types of cooling towers

By the type of irrigation system, cooling towers can be divided into:

- film;

- drip;

- spray;

- dry.

Based on the principle of atmospheric air supply, cooling towers are divided into:

- fan, when air is supplied by fans.

Advantages: high-quality, fast water cooling

Disadvantages: high energy consumption

- tower, when the air draft is created using a special tower design and its height

Advantages: low energy consumption

Disadvantages: slow water cooling

- open or atmospheric cooling towers that use the force of the wind and the natural movement of air masses as they move through the tower

Advantages: virtually no energy consumption

Disadvantages: slow water cooling, large size

- ejection, which uses the method of spraying water in special channels with natural air entrapment

Advantages: rapid cooling of water by creating a vacuum

Disadvantages: high energy consumption.

In the direction of movement of water and air:

- countercurrent

Advantages: in such cooling towers, the greatest temperature difference is created and, accordingly, heat transfer due to high aerodynamic resistance.

Disadvantages: large droplet entrainment, which is especially noticeable when there is a lack of return water replacement and in densely populated areas;

- cross

Benefits: Less drift.

Disadvantages: low aerodynamic resistance;

- mixed

Both counterflow and crossflow are used.

It is advisable to use a tower cooling tower in large industrial enterprises. The cross-sectional area of the tower should occupy at least 30-40% of the area of the sprinkler. Cooling towers of medium and small capacity can have a very different shape: cylindrical, truncated cone, or in the form of a truncated polyhedral pyramid. Cooling towers are usually made in the form of hyperbolic shells, which are optimal in terms of internal aerodynamics and stability.

Exhaust towers work in very difficult conditions: the shell of the towers is exposed to moist warm air in the cooling tower and cold air outside in winter, condensation forms on the internal surfaces. Thus, the choice of material is important.

In cooling towers, air convection is carried out by natural draft or wind. The height of the concrete cooling towers can be up to 100 meters. In this case, the irrigated area will reach 3500 sq.m. Basically, tower cooling towers are used to cool large volumes of water from thermal power plants or nuclear power plants.

Pros of tower cooling towers:

- profitability (no electricity needed);

- ease of use;

- location close to an industrial facility.

Minuses:

- large area for construction;

- great value.

Schemes of tower cooling towers with different patterns of air movement in the sprinkler are shown in Fig. Irrigation devices in all of the above cooling towers are of drip, drip-film or film type. Currently, cooling towers are mainly built with film and drip-film sprinklers with counterflow air flow, which have the greatest cooling capacity.

Figure: Schemes of tower cooling towers with different patterns of air movement and - with transverse; b - with cross-counterflow; in - with countercurrent.

The experience of using reinforced concrete in cooling towers shows that the shells of the towers are intensively destroyed due to the saturation of concrete from the inside with moisture and repeated freezing and thawing under the influence of outside air temperatures in winter. Metal frame cladding towers are built in areas with a harsh winter climate. They are pyramidal with a polygon or square base.

The timber frame is used in cooling towers with a small area.

the shape of the surface that describes the pipe in three-dimensional space is called a parabolic hyperboloid - a surface of the second order! Water is discharged in the focus of the figure and the effectiveness of this form is calculated mathematically - that is, the very unique case when there was first a mathematical theory, and then practice

The formula is elementary:

Well, here's how everything looks inside there: