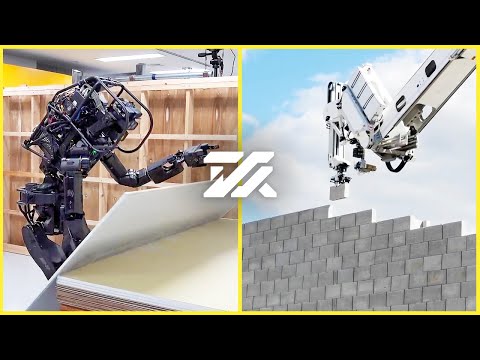

By Fastbrick Robotics, a company based in Perth, Australia has created a robot called Hadrian that does brickwork. The company claims that he is able to build the foundation of a house in two days.

But this robot, more like a regular truck, is just laying bricks.

It does it quickly, neatly and quietly. With speed and precision incomprehensible to the average worker. A good sober builder lays 500-600 bricks a day (and even fewer cinder blocks). The house, which a team of workers would have built in 16-17 days, will be built by Hadrian in two days (needless to say, he doesn't go to lunch and sleep).

To start the process, you need to put several beacons along the dimensions of the structure, cross your fingers and start executing the program. To recreate the atmosphere of the construction site, the selection mat recording can be turned on in the truck's radio.

Hadrian can shrink material to size, mortar and lay 1,000 bricks per hour, 20 times faster than average bricklayer speed. Hadrian makes it possible to build modern brick houses at a rate of 150 buildings per year (assuming the telescopic arm does not tip over).

Fastbrick Robotics Hadrian.

The giant robot arm moves using fixed marks that take information from the design of the house in a 3D CAD application. It automatically corrects itself 1000 times per second to prevent vibration or electricity interference. There are also lasers for position triangulation, but this all sounds very complicated.

The advantages would seem to be that the construction robot can work 24 hours a day, regardless of weather conditions or breaks. What a joy it is to live next to a construction site, where such a robot works around the clock and literally never gives you the opportunity to sleep!

Promotional video:

“Hadrian is cutting the total construction time for a standard home by about six weeks,” Fastbrick Robotics CEO Mike Pivak told Gizmag. “Due to the high level of precision we have achieved, most of the other components such as kitchens and bathrooms, and rafters can be fabricated in parallel and simply installed once the masonry is complete.”

If you're suddenly worried about robots taking away all our good jobs in construction and coffee making, consider that Hadrian will not only reduce waste and emissions (it’s supposedly electric), but it will also create jobs. In Australia, bricklaying is likely to be part of a career of the past, as most artisans are now in their 50s and are approaching retirement age. Bringing robotics to work, the inventors hope, will create jobs for young people.

Fastbrick Robotics Hadrian.

Swiss engineers have created a robot that replaces several professional construction workers. The future is today! It was this motto that guided the Swiss innovators when they decided to create a robot designed to perform reinforcement work in construction.

Researchers at the Swiss Higher Technical School of Zurich are working on a project for the world's first house to be designed and built using digital manufacturing processes. The house was named DFAB House.

Robots are capable of making a brick cladding in a day, and using 3D printing, you can build bridges right on the site - digital technologies are designed to radically change the approach to construction. A team of researchers from the Swiss Higher Technical School of Zurich is currently testing the operation of these technologies both in specially designed test environments and in real conditions. DFAB House will be the first home to be not only designed on a computer, but almost entirely built using digital building processes.

The three-story building is being erected in Dubendorf, Switzerland, on the premises of the NEST research center, a joint project of the Swiss Federal Laboratory for Materials Science and Technology (Empa) and the Swiss Federal Institute for Water Sciences and Technology (Eawag). Scientists from various fields are working on the implementation of the ambitious project, including architecture, robotics, materials science, structural analysis and research on social and environmental responsibility. As a result, the DFAB House construction process will use four innovative construction technologies developed by researchers from the Swiss Higher Technical School.

Fastbrick Robotics Hadrian.

The Swiss decided that it would be best to build an entire house to demonstrate the full potential of the device. A monolithic high-tech house, which is at the same time a laboratory where the capabilities of the robot are tested, has an area of 200 sq. m and a height of three floors.

The construction of the house is planned to be completed in 2018, but for now the scientists are improving their device, which, according to them, should completely replace the workers involved in the reinforcement of structures and their pouring with concrete.

The robot moves on a tracked chassis. The height of the robot is 2 meters, and the highly mobile "arm" - the manipulator significantly expands the area of work. At this stage, for accurate positioning on the construction site, the robot needs helpers - people.

Engineers put reinforcement into the robot's hopper, then lay out on the surface of the foundation - markers - special marks necessary for their reading by the robot's electronic "eye". The robot, having oriented itself, moves along the marks and assembles the reinforcement cage in accordance with the project and the loaded specification.

Fastbrick Robotics Hadrian.

So far, the robot independently connects only horizontal reinforcement and cross ties. Vertical rods are installed by people, but thanks to precise positioning and 3D modeling, the robot is able to quickly knit the most complex reinforcement cages with a curved surface.

After installing the frame, it is poured with a special concrete mixture with plasticizers that increase its workability. Thanks to modern digital technology and 3D printing, which is also used in the construction of the pilot building, the scientists hope to create a real robotic complex operated by one operator.

This should speed up all stages of construction and reduce the so-called. "Human factor" to a minimum. In addition, the introduction of innovations will make it possible to build houses of non-standard architecture with complex facades, arches and an unusual curved interior.

Americans are developing a construction robot that designs and prints houses by itself.

When it comes to building robots and 3D printing houses, most people envision high-tech human-controlled machinery. Such robots, at least, need one operator and assistants - people who will serve them. Engineers at the Massachusetts Institute of Technology decided to look into the future and developed a prototype of an autonomous construction robot.

The robot is a self-propelled chassis. In front of the "builder" there is a "hand" - a smart multifunctional manipulator. Behind the "hand" with a computerized control mechanism is a platform with building materials. At the moment, to work out the concept, the robot carries containers with polyurethane foam (polyurethane foam) and foam concrete, from which it builds a domed house using the technology of fixed formwork. First, the external and internal PPU-wall is erected, and the gap is then filled with foam concrete.

The robot spends about 10-14 hours to build a dome with a diameter of 15 meters. At the same time, the robot does not need to be controlled by a person and, having orientated itself on the terrain according to the marks, decides how to build the structure. If the solution runs out, the robot goes to the base for refueling, after which it continues building the house. According to the developers, the choice of materials and construction methods is due to the fact that it is easier to "teach" the robot to build and make appropriate adjustments to the software.

The next step is to use concrete for construction, which is modified with special additives for mobility. A set of spray nozzles is provided for working with different mortars. In addition, as the robot improves, it will be taught to work with fittings and a welding machine. And an excavator bucket. As conceived by the engineers, over time, based on the prototype, it will be possible to create a fully autonomous robot.

For example, one of the scenarios might be to send several construction robots to a remote area, where they interact with each other to start building structures. Moreover, the robots, depending on the initial data and the availability of building materials, will themselves calculate the parameters of the structure and decide what and how to build from. Additionally, the robot will also be equipped with solar panels and a set of interchangeable "arms".

Students of the School of the Architectural Association in London decided to prove that a robot can plan a house from scratch, without blueprints and pre-prepared materials. The experiment was crowned with success.

The robot looks at the trees and immediately sees the house. Cameras scan tree trunks, using specially written algorithms, the robot calculates the shape of the wood, finds centerlines and estimates the individual strength of the material, after which, relying on the originality of the shape of the provided material, creates a building project.

In an architecture laboratory, a robot gets to work, cuts and shapes logs, making blanks for the future structure, as if cutting out pieces for a puzzle. Of course, it was not without human help, it was people who created the vision of the machine, and the final assembly of the house is also on their shoulders, the robot cannot yet build on its own. But this is just a matter of time and desire. The main thing is that he knows perfectly well how to do it, and he is not alone. Modern drones are already capable of erecting towers, and for the construction of space stations, spider robots are being developed that have mastered the technology of 3D printing.

Robot for reinforcement work.

Massachusetts robot builder.

Massachusetts robot builder.

Robot for reinforcement work.

Robot for reinforcement work.